Bill Monk

Well-Known Member

Just bought a distributor and ignition box from 4secondsflat. This is a quote from their tech instructions:

"Hot Rods, Muscle Cars, Classic Cars or nearly any performance application the Vacuum Can is connected to the CONSTANT Ma nifold Vacuum source. Doesn't matter what you read on the internet if you don't have any computer controls, Catalytic Converters or other emissions equipment it goes to CONSTANT. End of discussion."

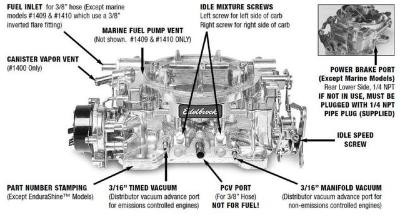

This is contrary to everything I thought I knew. I have always plugged the vacuum advance to the ported hole at the top of the carb so that you get advance as vacuum increases. Throw some input at me!

"Hot Rods, Muscle Cars, Classic Cars or nearly any performance application the Vacuum Can is connected to the CONSTANT Ma nifold Vacuum source. Doesn't matter what you read on the internet if you don't have any computer controls, Catalytic Converters or other emissions equipment it goes to CONSTANT. End of discussion."

This is contrary to everything I thought I knew. I have always plugged the vacuum advance to the ported hole at the top of the carb so that you get advance as vacuum increases. Throw some input at me!