torredcuda

Well-Known Member

Great work!

That's AWESOME!!!!Love seeing you hand fabricate parts where most would just buy the repro part and either install whole or cut and use what they needed from it. I spent a 9-10 yea hiatas from my real career doing autobody for a living but my real career was in precision sheet metal shops. I ran almost every machine in the shop - shears, punch presses, press brakes etc. along with programming, engineering, supervising etc. so I know what it takes to make nice parts. I hand fabricated floor pans for old `69 Barracuda including the stiffening ribs and plenty of other patch panels over the years.

Absolutely sir!I found that replacing the hole part was faster than peacing it. I also knew that it was all new. These cars take a lot longer than we figure in the beginning. Mine was on the 5 years outside without working on it every day. But never have regrated it now that I am going to car shows and winning trophy's and Plack's. You can say I did this and be proud of what you were able to do. Not taking it to a shop to do the work makes the car more personable to you and it is a part of your life. Keep us updated on the progress keep up the good work. Russ.

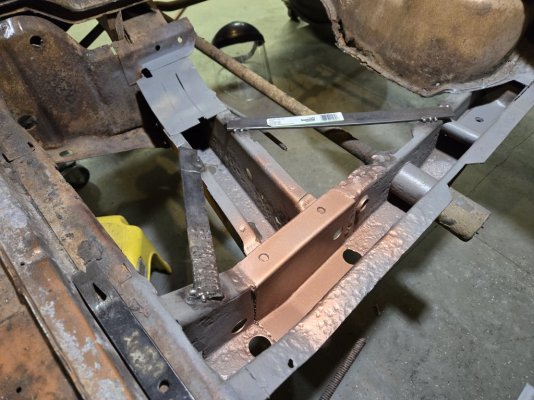

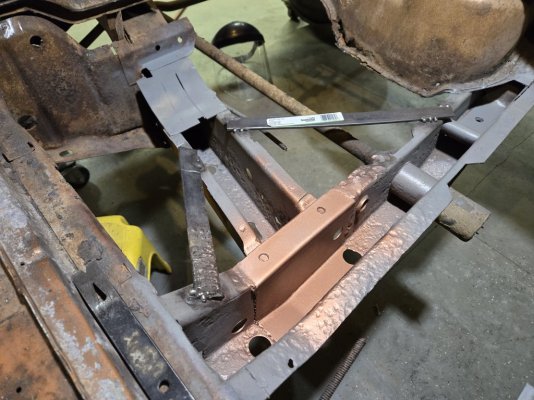

Yup...probably should have replaced the entire crossmember. But, I wanted the experience of working with that 14 Gauge metal and hand fabricating the piece to my measurements and design. Plus I wanted the experience of messing it up and working through the problems....I’ve always been hard headed like that...there's always the easy way, which is nice to have in the back of my mind if I really mess up. I love the challenge though!Sometimes it`s easier/better to repair a section other times replacing the whole piece - depends on the extent or the rust/damage. I spliced in homemade sections of the rear frame rails on my Barracuda because only the rear area was rusted and back in the early 90`s they didn`t reproduce them.

I tested the Ameter, Fuel Guage, and Coolant Gauge for a simple operation check with a 9 Volt Battery. All 3 Gauges responded with the test voltage. Now I need to build a low-voltage electrical system based on resistance to see if the Gauges read accurately.

I tested the Ameter, Fuel Guage, and Coolant Gauge for a simple operation check with a 9 Volt Battery. All 3 Gauges responded with the test voltage. Now I need to build a low-voltage electrical system based on resistance to see if the Gauges read accurately.

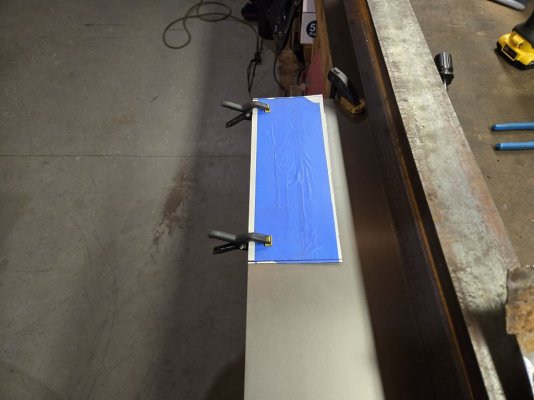

I'm gonna try polishing out the scratches and try to save the original. We'll see how it goes!I think the plastic gauge cover is available repopped